Stirling Engine

(2018)

The MIT Pappalardo apprenticeship is a two-year machine shop focused program for students in mechanical engineering. Each year seven juniors are invited to participate in the program and serve as mentors in MIT’s machine shop while continuing to refine their own machining skills. In the first year of the program, each apprentice proves their machining chops by fabricating a Stirling engine from raw stock and a set of drawings.

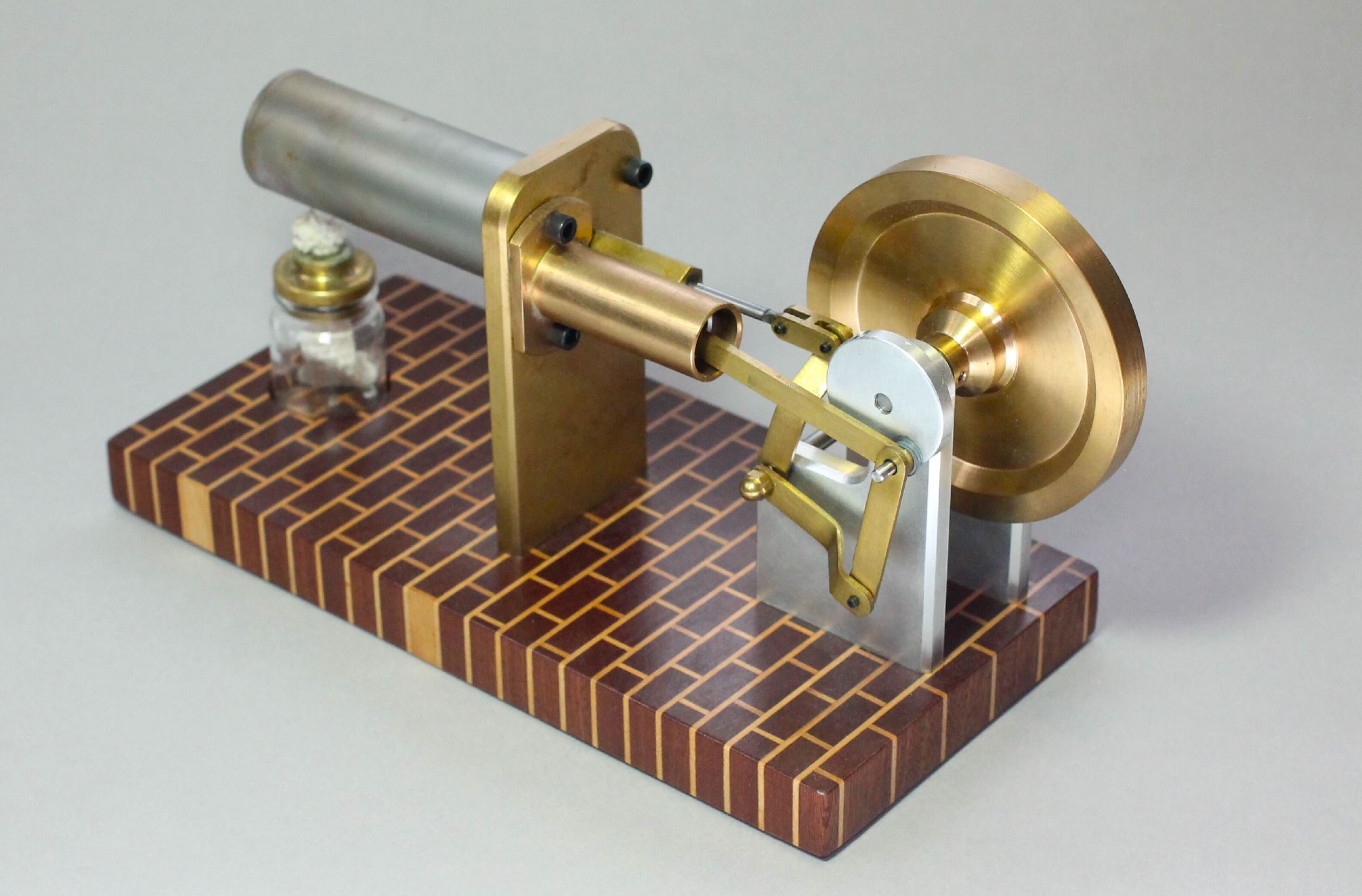

The engine is composed of 23 machined parts. Aluminum, brass, and several types of steel are all used, so a thorough knowledge of speeds and feeds must be applied to get the appropriate finishes on parts.

The engine is composed of 23 machined parts. Aluminum, brass, and several types of steel are all used, so a thorough knowledge of speeds and feeds must be applied to get the appropriate finishes on parts.

The engine generates power through a piston that shuffles air between the hot and cold sides of the displacer cylinder (dark grey cylinder). Heat is provided to one end of the displacer cylinder through an ethanol lamp.

The engine generates power through a piston that shuffles air between the hot and cold sides of the displacer cylinder (dark grey cylinder). Heat is provided to one end of the displacer cylinder through an ethanol lamp.

The base plate is made out of Sapele and Maple using a traditional end grain cutting board technique.

The base plate is made out of Sapele and Maple using a traditional end grain cutting board technique.

Video of engine running at full speed. The fastest recorded speed was 630 RPM.